A building is in many ways a work of art and an original and imaginative façade or wall cladding can give it real character and originality. Aluminium is the ideal choice for creative and functional architecture. Because of its distinct properties, it can be shaped to custom designs of long-lasting durability. Better still, aluminium can be recycled repeatedly without any loss of quality, making it a prime choice for sustainable and “green” construction. It conforms to the Euroclass A1 fire standard.

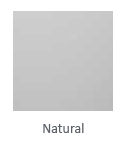

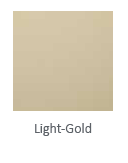

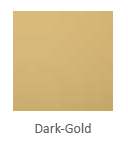

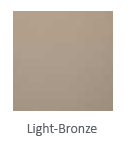

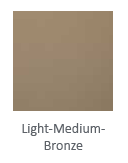

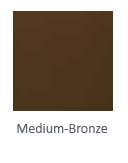

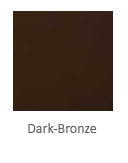

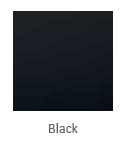

Colours & Surfaces

The special surface and deformation qualities of aluminium allow it to be creatively shaped to your design. Its facility for bending, perforating, punching and expanding has naturally made it the modern material of choice for creative wall cladding. In combination with either natural or colour anodising, it creates a unique look-of-the-building envelope.

This can give you inspiration for more creative architecture!

Creative Architecture with Aluminium Duffel

We produce a.o. several alloys suitable for anodising, optimised for their architectural end-use. These anodising qualities are at best used for exterior façades, roofs, balconies, sun ventilation screens and interior ceilings, pillars, or wall cladding and escalator casing.

After natural or colour anodising the aluminium substrate is weather, corrosion and UV-resistant but keeps the authentic metallic gloss as well as the durability inherent to aluminium.

To fulfil contemporary demand for critical applications developed a premium alloy: 55HX®. This alloy – which offers guaranteed colour and gloss uniformity and a unique look between production batches – is the state-of-the-art material for architectural applications. 55HX® conforms to the European Class A1 fire standard.