Project Description

Partnering with your aluminium material supplier to achieve certifiable sustainability improvements.

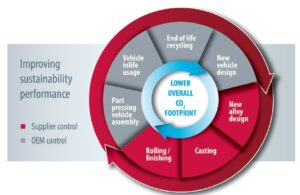

Automotive manufacturers are faced with increasingly stringent emissions standards, and one of their greatest challenges is how to effectively track and measure life-cycle carbon footprint reductions, and leverage that data as a marketing advantage.

The use of aluminium sheet in vehicle design is an important lever to reduce the overall CO2e footprint of new vehicle production and in-life usage. This is due in part to the lower amount of emissions it takes to produce aluminium, but also the important role aluminium can play in lightweight design to reduce emissions during the life of the vehicle on the road.

Aluminium suppliers experienced in complying with standards that have been historically stricter, usually in

the European market, offer technical experience, as well as an array of analytical and material development processes to meet that challenge. Processes include the ability to drive multidisciplinary improvement from original vehicle design (involving alloy selection) and production through the collection and separation of OEM scrap for dedicated OEM-specific reuse and predictable future emissions reductions.

Sustainability as part of the performance equation

Only when sustainability is considered as one of the main performance goals in an integrated, multidisciplinary process from cradle to grave can OEMs achieve step-by-step sustainability improvement. As a certifiable emissions target baseline is set for each vehicle model, an experienced aluminium supply partner will define with the OEM specific initiatives and projects to achieve the OEM-sustainability goals.

This can involve initiatives focused on selecting the appropriate aluminium alloys and optimising the design for outer panels, inner panels and a variety of medium- to high-strength structural applications to significantly reduce the overall CO2e footprint, not only during new vehicle production, but also in service use. In fact, experience has shown that an opportunity exists to further reduce the vehicle production accumulated emissions due to aluminium sheet by 20 to 25 percent from today’s aluminium vehicle level, while at the same time achieving an additional 6 to 8 percent CO2e per km emission savings due to the further vehicle weight reduction of circa 10 percent.

Independent certification enables ‘sustainability improvements’ promotion messages with credibility

Perhaps the greatest advantage to partnering with an experienced aluminium supply partner is its high level of expertise at life-cycle analysis and a geographically appropriate certification process. The wider the data sampling availability of existing applications, the more accurate the predictions, as the partner monitors CO2e of its existing alloys annually. OEMs can use the partner’s field-proven software add-ins for life-cycle analysis simulations. Best of all, every analysis provided is independently certified by a third party with authority, often approved by the OEM partner.

This transparent process is helping global automotive OEMs chart their path toward a more sustainable future.