About us

Not your normal aluminium supplier

Superheroes make sure everybody is safe. So do we. Our heroes are the more than 1000 people working for you in our plant. We make sure they can do their job in the best possible, safe circumstances. In other words, working with us is dealing with a supplier that provides you with the best product, made by the best people. You get two for one. It’s beyond the material. Or as we say it: mind over metal.

You can find a lot of companies, selling you aluminium semi-finished products. Sure. But there’s only one Aluminium Duffel. What sets us apart is that we change the game. Not with highbrow chitchat, but with fearless action. The kind of action you would normally expect from superheroes like Batman.

Strange comparison? Not at all.

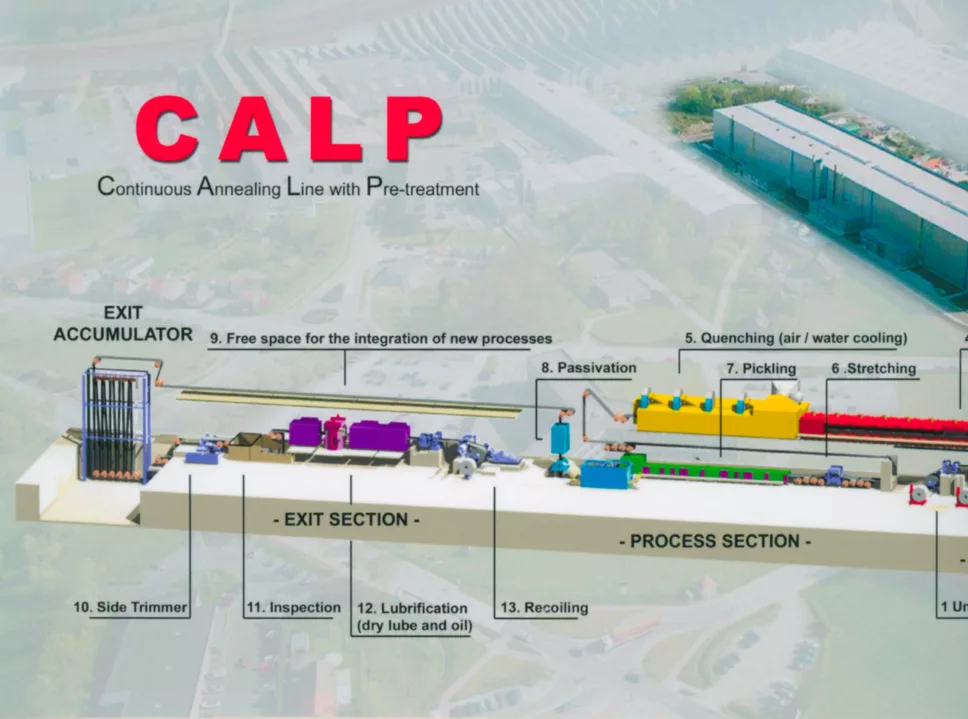

Batman has a state-of-the-art Batmobile. We have the widest automotive cold-rolling mill in Europe and a Continuous Annealing Line with Pre-Treatment (CALP). We’ve probably supplied the body panels for the Batmobile, come to think of it.

Every employee at Aluminium Duffel is committed to achieving consistent results and meeting challenges as a team. We want to empower each other and rely on skillful colleagues so we can excel in serving our customers.

People are our most valuable asset, and their safety is a top priority. We want them to be the best version of themselves in all their diversity. To be heroes in what we do we must focus on the satisfaction of our customers, employees and neighbours in our local community.

We want to be a courageous game-changer in our field, pioneering innovative technologies to help our customers meet their goals. Employees are encouraged to find time for self-reflection and foster personal growth while remaining focused on making our world a better place.

Today we are changing the game, to make the world a better place

We happen to have the perfect material for it: aluminium can be recycled endlessly without losing its lightweight, strong, non-corroding characteristics. Maybe you should try it one day.

Can you make the finest aluminium around while making the world a better place? Well, you know the answer.

Our certifications

Production process

We go out every day, striving for excellence.

Serving people, the best we can.

Aluminium Duffel manufactures high-value aluminium products. Our operations are situated downstream in the aluminium value chain. We are not a producer of aluminium, but we transform primary aluminium, alloying elements, internal and external production scrap in a sustainable manner into high-quality rolled aluminium coils, sheets and strips.

Our semi-finished products serve as fundamental components for our customers, who are active in diverse markets such as automotive, construction, medical care and various other industries.

In our casthouse we process aluminium slabs in customised alloys from a combination of internal and external production scrap, primary aluminium and alloying elements. We use electric channel induction furnaces to remelt the aluminium. These furnaces have no direct GHG emissions, as they do not use natural gas, but electricity. To cast the aluminium, we use conventional and electromagnetic casting.

In our rolling department, slabs are rolled into coils after passing through a preheating cycle. Next, the slabs are hot-rolled and then undergo additional processing in the cold-rolling mills to produce the thickness requested by the customer. Depending on the material specifications required by the customer, parameters such as temperature, emulsion and thickness are adjusted during the rolling process.

Coils are subjected to a variety of production steps on our finishing lines to meet further customer requirements and are finally transformed into coils, sheets or strips for shipping.

Automotive orders are processed on our Sexto 2, the widest cold rolling mill in Europe, and then pass through the Continuous Annealing Line with Pre-treatment (CALP) for various annealing and surface treatments.

Specialised finishing installations are available to process non-automotive orders. Cold-rolling, degreasing, stretching, slitting, cross-cutting, lubricating and packaging are applied in accordance with customer specifications.

Aluminium can be endlessly recycled without losing its properties. Internal and external production scrap is recycled during our production processes. Closed-loop partnerships are set up with our customers to drive sustainability even further.

Your global partner

We deliver our innovative and sustainable aluminium products to international customers around the world.

200 KT annual production volume of high-value aluminium rolled products

Our real superpower lies with our people.

Some heroes can see right through buildings.

The heroes in our company see the future.

Our leaders go out every day, striving for excellence.

Serving people, the best they can.

We have strong leaders who walk alongside the Aluminium Duffel heroes. They want them to be the best version of themselves, in all safety.

Join a winning team

At Aluminium Duffel, we have employ-heroes in all shapes and sizes. Are you driven to change things, find ways to make processes more sustainable and face challenges,? Then we should sit down and talk. Tell us your strengths and weaknesses (kryptonite?), we’ll show you our magic.

Job variety, a positive culture and impressive machinery is what I like about Aluminium Duffel.