Architecture and Construction

Facade cladding

Aluminium Duffel has been an innovative leader in architectural applications of aluminium for over 30 years. Whether it's exterior façades, wall cladding, ceilings, roofs, balconies, pillars or escalator casings, Aluminium Duffel provides eye-catching and durable materials for any architectural application.

But what’s so special about our dedicated cladding brands? Our showcase products, 55HX® and 151EX®, can be anodised for high and reliable endurance while maintaining their unique metallic gloss. In addition, creative designs and colours can be applied. Architects love this material and have used it around the world for iconic buildings. We help them win awards by offering façade cladding products in a wide range of colours. More customised colours are available on request. These are anodised colourings and not coatings, so they have all the benefits of our premium aluminium anodising quality – durable, non-corrosive, scratch-resistant and optimised surface quality. 55HX® offers excellent colour consistency. For your projects with specific sustainability goals, 55HX® aluminium is also available with recycled content. For more information contact us!

Anodised colours

The samples you see here are our standard anodised colours. Other colours are possible for large orders. Please contact us for more information.

What is anodisation?

Aluminium is anodised to protect it from external corrosion and to apply an attractive gloss. Anodisation is an electrochemical process that treats the aluminium at an atomic level and leaves a protective barrier on the surface. The anodic layer is an integral part of the aluminium surface. Aluminium can also be dyed during this anodising process to create a wide range of authentic metallic colours.

Key benefits of anodising

- Weather-, corrosion-, and UV-resistant while maintaining its metallic surface aspect, even after colouring

- Durable, light, non-combustible

- Colouring is an integral part of the anodising process and not a coating

- No filiform corrosion or colour fading

Cleaning and degreasing followed by etching. Etching removes the natural but unevenly distributed oxide layer of aluminium. In the anodising bath, it is regrown but evenly distributed over the surface so that the colour & sheen are as uniform as possible.

The actual electrochemical process that creates a new, optimised protective layer.

The dyes are impregnated in the pores of the aluminium. The colouring is an integral part of the surface and not applied as a coating. Sealing: this step seals the pores of the aluminium surface to preserve the colour and the surface finish.

Anodising process

Anodising coils is a continuous process that consists of several steps.

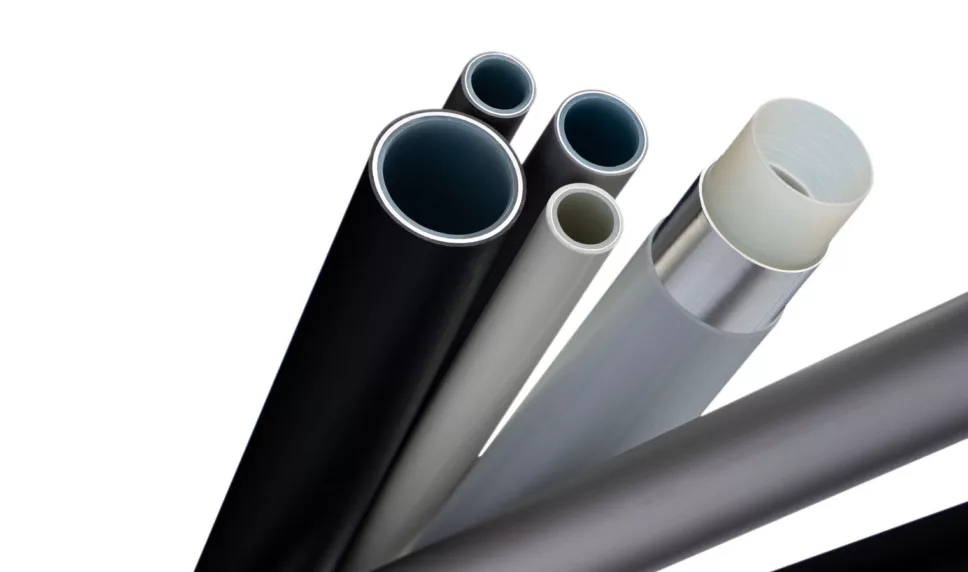

Multilayer pipes

Aluminium Duffel has been an active player in multilayer piping since the technology emerged more than 25 years ago. Multilayer pipes or composite pipes are used in many household and industrial applications: sanitary and drinking water installations, central heating and floor heating, gas pipes and pipes for special liquids, and many industrial fittings. Aluminium Duffel has developed the unique PIPELITE® series of alloys in various thicknesses and widths that offer optimum performance for these different applications.

PIPELITE® aluminium alloys comply with the relevant European Standards for composite pipes. These products offer numerous benefits for all modern multilayer pipes and feature high pressure resistance, maximum downgauging in thickness and weight, excellent bendability combined with superior form stability, and extremely high expansion characteristics.

We also develop bespoke alloys for customised applications. Our engineers are at your service with their experience and expertise to design best-in-class, semi-finished products for even the most ambitious projects.

Dimensions

Thickness range: 0.1 - 1.0 mm

Width: 15 - 1650 mm

Coil outer diameter: max. 1800 mm

Other dimensions upon request

Our brands

55HX®

55HX® aluminium is the material of choice for creative architects who want to design state-of-the-art façades, wall cladding, ceilings, roofs, balconies, etc. in high-profile projects. Our 55HX® alloy is anodised for increased corrosion and scratch resistance while keeping its unique metallic texture. Anodising with colouring is also an option. 55HX® aluminium alloy has excellent bending and forming properties, is easy to clean, non-combustible and durable. For your projects with specific sustainability goals, 55HX® aluminium is also available with recycled content. For more information contact us!

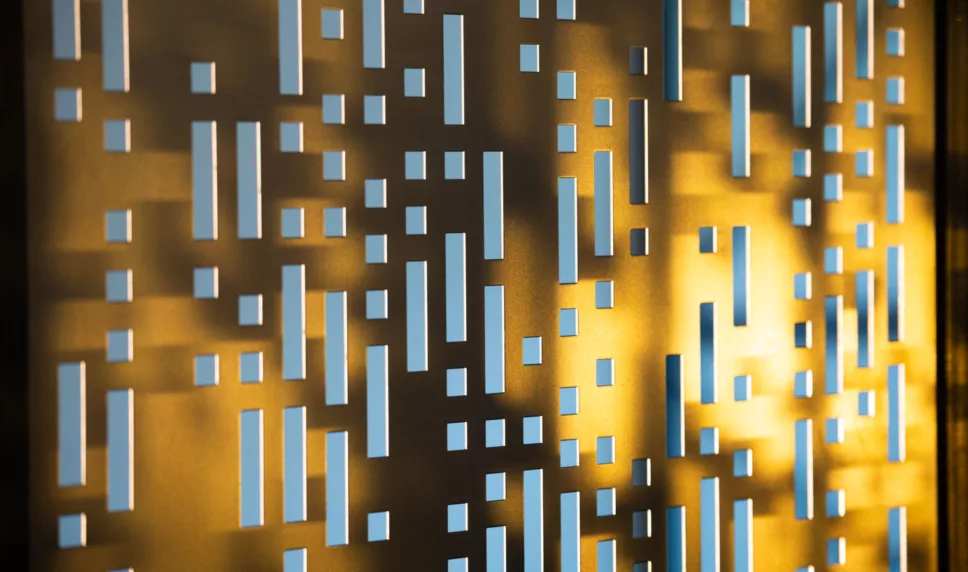

151EX®

151EX® aluminium alloy can be used for a unique expanded mesh design in wall cladding. This material is light but very strong and weather resistant. Typical designs incorporate apertures for both functionality and aesthetics but also for varying levels of sun filtration, visibility and privacy. Our 151EX® alloy is mainly used for eye-catching exterior cladding of façades but can also be applied to interior elements such as balustrades, ceilings, etc.

Decolite®

Decolite® aluminium alloy combines a premium anodising quality aluminium with a uniform brush surface that creates an attractive stainless-steel look and feel. Typical applications include interior decoration, name plates and signs, door and cabinet panels, automotive trims, side panels of escalators and elevators. This material is also available in a brush quality that can be lacquered.

PIPELITE®

PIPELITE® aluminium is offered in an unmatched selection of alloys to meet the most stringent requirements of modern multilayer pipes. This product is the result of optimised thermo-mechanical processing and is specifically designed for use in composite pipes. PIPELITE® aluminium is used in applications for sanitary and drinking water installations, floor heating, pipes for gas and special liquids, industrial applications, etc.

Your global partner

We deliver our innovative and sustainable aluminium products to international customers around the world.

200 KT annual production volume of high-value aluminium rolled products