Automotive and Transportation

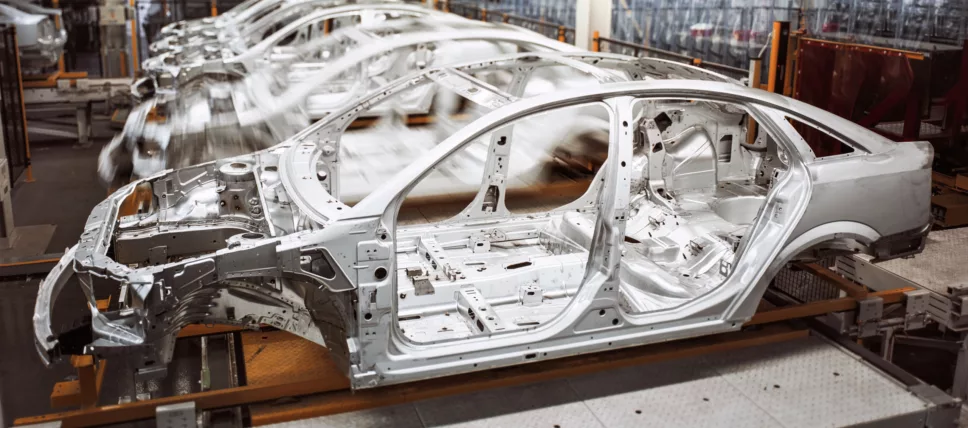

Body panels

Vehicle manufacturers allow no compromises when it comes to safety and design. They need to be able to rely on best-in-class suppliers for their raw materials. We

produce high-performance alloys for inner and outer body panels for premium car manufacturers around the world. These alloys guarantee optimum surface appearance, formability and strength.

We offer both 5xxx and 6xxx series sheets, including wide formats of more than 2000 mm, with numerous textures, passivation and lubrification options. Our ECOLITE™ aluminium brand is ideal for inner panels and structural components while SUPERLITE® products are specifically designed for outer panels. Our innovation centre drives our customers’ success with new alloys featuring better formability and enhanced productivity characteristics.

Technical specifications

Brands: ECOLITE™ aluminium, SUPERLITE® aluminium

Alloys: 5051A, 5182, 5754 (inner panels); 6016 (inner and outer panels).

Tempers: 5xxx: O/H111 – 6xxx: T4, T6

Dimensions: thickness 0.8-3.5 mm – width 40-2150 mm

ID: 508, 609 mm

OD: 900 - 1800 mm

Texture: EDT, MF

Treatments: passivated, oiled, hotmelted

Not every combination of alloy/temper/dimensions is possible. Bespoke combinations are possible upon request.

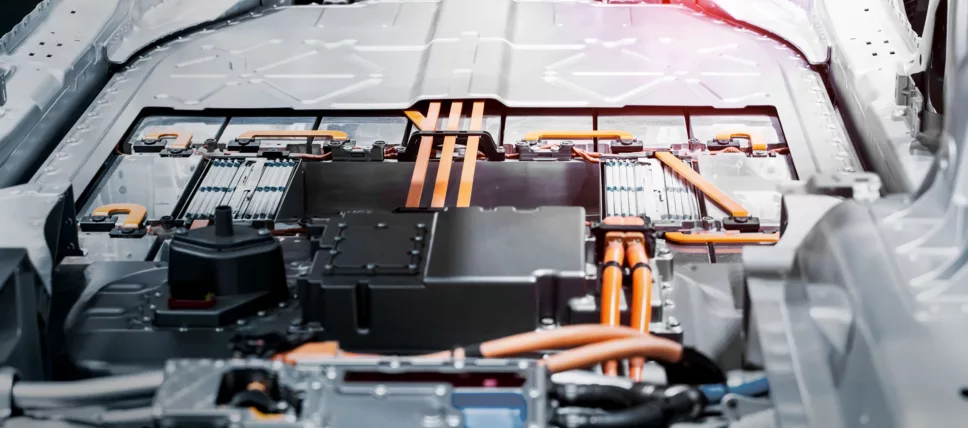

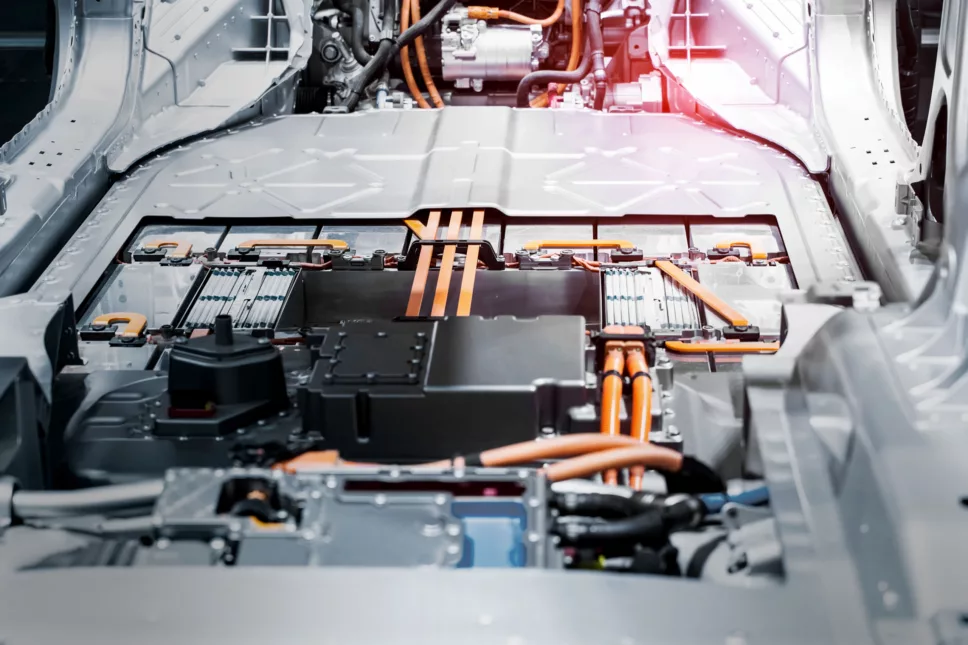

Battery casings

The lightness and strength of aluminium alloys make them the ideal choice for the battery casing in electric vehicles (EVs). Reducing the weight of EVs to optimise their range is a major goal in electric vehicle design. Our special alloys are strong and corrosion resistant, enabling carmakers to produce battery casings with excellent crashworthiness and intrusion resistance.

Our 6xxx series ECOLITE™ alloy is recommended for battery casings due to its high strength. With extensive expertise in 6xxx-series alloys and a commitment to consistent quality, Aluminium Duffel stands as the trusted partner for innovative and eco-friendly battery casing solutions.

Truck fuel tanks

Truck manufacturers rely on our high-quality sheets and coils which are designed specifically for the inner and outer sections of fuel tanks for medium and large trucks. Our special alloys are engineered to meet the stringent requirements of this industry, with a particular focus on surface quality, formability and weldability.

Outstanding formability facilitates the design of complex tank shapes with deep-drawing, while superior surface quality ensures optimum exterior aesthetics for these critical parts without the need for extra coatings or painting.

Our special alloys for fuel tanks offer all the benefits of aluminium – lightweight, high strength and corrosion resistance. These properties increase safety and crashworthiness and reduce the risk of fuel spillage in the event of an accident, as such providing better protection of our environment.

Technical specifications

Alloys: EN 5052 – EN 5754

Tempers: H12 – H22

Dimensions: width: up to 1640 mm – gauge: typically 2.5 mm

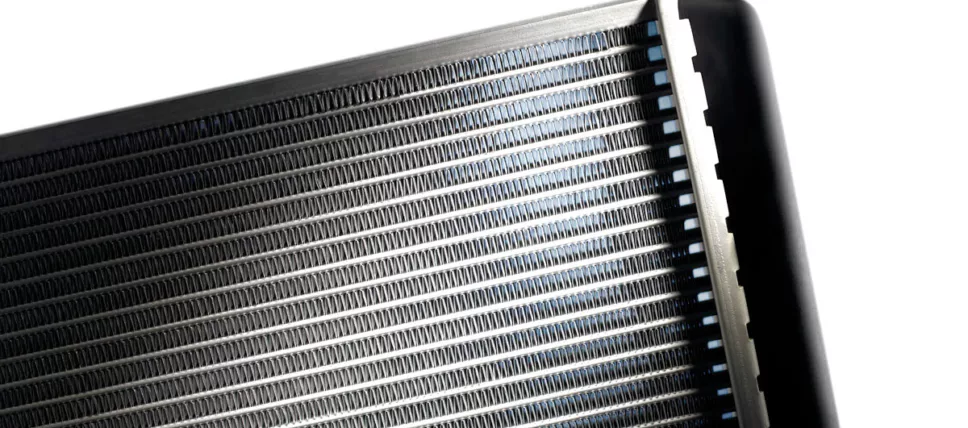

Heat exchangers

Aluminium heat exchangers are everywhere: vehicle engines, batteries and climate control in cars, HVAC at home and in the office, and industrial applications ranging from cryogenic gas processing to windmill oil cooling. Aluminium has excellent thermal conductivity combined with low weight and a long corrosion life. Our experts work together with customers to optimise material properties for their applications.

Aluminium Duffel has many years of experience and expertise in the heat exchanger market and offers a wide assortment of bare, non-clad aluminium products especially designed for the different heat exchanger components: base plates, tubes, fins and collar fins. We have experience in slitting light gauges for tubes and fins and we also offer narrow widths. Thicker gauges can be slit for base plates or other components.

Our brands

SUPERLITE®

Our innovative SUPERLITE® aluminium alloy is the ideal material for all outer panels in car body design and closures. The alloy can be used for roofs, doors, trunk lids, hoods, side panels, etc. SUPERLITE® aluminium has excellent surface finish properties with good hemming and forming characteristics that enable cutting-edge lines in car body design.

ECOLITE™

ECOLITE™ aluminium is a highly formable alloy, making it ideal for inner car panels that require deep drawing and for structural components needing higher yield strength and enhanced crash performance. Our ECOLITE™ alloy is the perfect solution for meeting demanding safety performance requirements in the latest car designs. Additionally, ECOLITE™ alloy is recommended for battery casings due to its high strength and crash resistance.

FORMLITE®

FORMLITE® aluminium is especially suited for deep drawing and stamping of mass-produced objects or small series of parts in the automotive, packaging and medical industries. These applications generally require narrow and deep shapes. Maximum downstream processing speeds of complex objects can now be achieved thanks to the highly consistent mechanical properties of FORMLITE® aluminium.

BENDLITE®

BENDLITE® aluminium alloy offers excellent bending properties with short radii for use in all kinds of cabinets and cases. BENDLITE® aluminium has excellent formability and allows bending up to 180° in all directions. Optimal flatness and highly consistent material properties guarantee reproducibility in your production process. BENDLITE® alloy also allows significant cost savings thanks to maximum material downgauging while maintaining strength.

Your global partner

We deliver our innovative and sustainable aluminium products to international customers around the world.

200 KT annual production volume of high-value aluminium rolled products