Newsroom

VVO6 revamp a huge success

The VVO6 is one of the four pre-heating furnaces used to heat slabs before they go to the hot mill. In 2020, we started conversion works on this furnace, which turned out to be a major revamp operation involving many departments in our factory.

New insulation

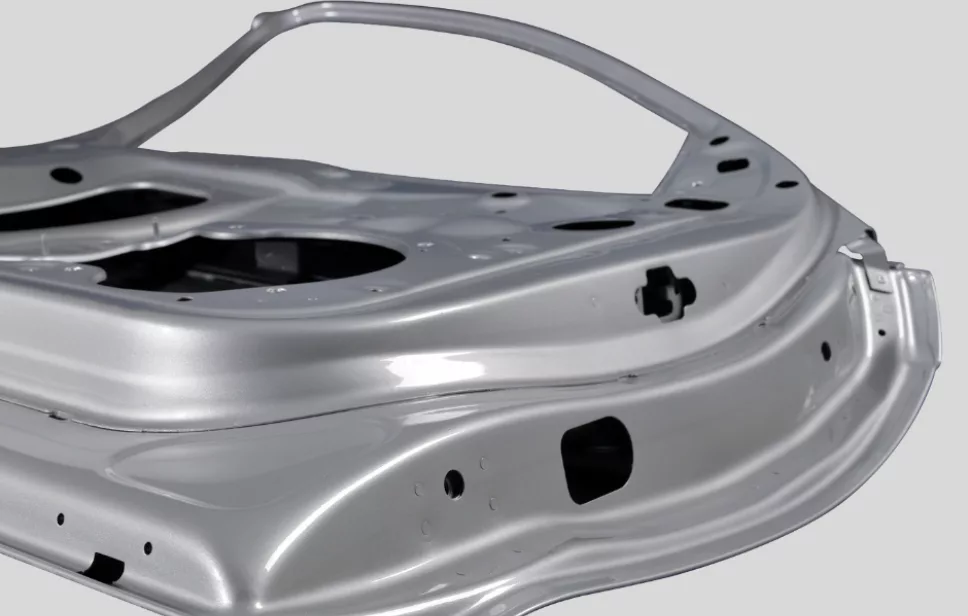

The rebuild was necessary because the insulation need to be replaced, and in some parts of the furnace the insulation had disappeared completely. This constituted a serious fire hazard. To perform the works, the furnace was emptied completely from the inside, so only the outer structure remained. You can see this on the picture in the bottom-left corner. The interior was then reinsulated with several layers and a heat-resistant stainless-steel sheeting was applied to seal it all off.

Preparing for automotive

A second goal of the revamp was to prepare the furnace for automotive products. To achieve this, various other adjustments were made:

- plug-in elements were added to measure the temperature of the metal

- pilot burners and gas supply were installed for accurate temperature control

- the door openings were widened

- software modifications

- heating elements installed in the doors

In total, this project took almost two years to complete. Different departments at Aluminium Duffel collaborated intensively: Maintenance & Production, Process Technologists, Technical Managers and Engineers, Breakdown Maintenance, Planning and Engineering.

It was a busy time for these teams, but the results are impressive. The furnace is now safer and ready to process automotive products more efficiently. In addition, the furnace is also more sustainable as we achieved an energy saving of no less than 20%.

Excellent teamwork between the various departments made this project a huge success. We would like to thank all team members who contributed to this project for their hard work and dedication!