Newsroom

Duffel, 26 September - Aluminium Duffel is proud to announce the launch of its new logo and at the same time they celebrate the commissioning of their new milling installation.

Mind over metal

The new logo, which is shaped into a heraldic shield, is a powerful symbol that reflects the company's core values: Change & Courage, People & Power, and Excellence & Teamwork. The shield is made up of three dynamic, red lines. The lines symbolise movement and strength – essential elements of both the aluminium products and the organisation itself. In addition to the new logo, Aluminium Duffel also introduced a new baseline: "mind over metal". This phrase embodies the spirit of the organisation. It means we do more than just produce metal, we make metal with a purpose behind it.

"The new brand identity and logo are a promise to our customers and stakeholders and a tribute to our strong team. Every employee is a hero who contributes to our success and future every day. In recent years, we have experienced several acquisitions and defied the energy crisis. Thanks to our team, we got through this period well. There is no better way to honour this than with a strong symbol," says Koen Libbrecht, General Manager at Aluminium Duffel.

New Milling Installation

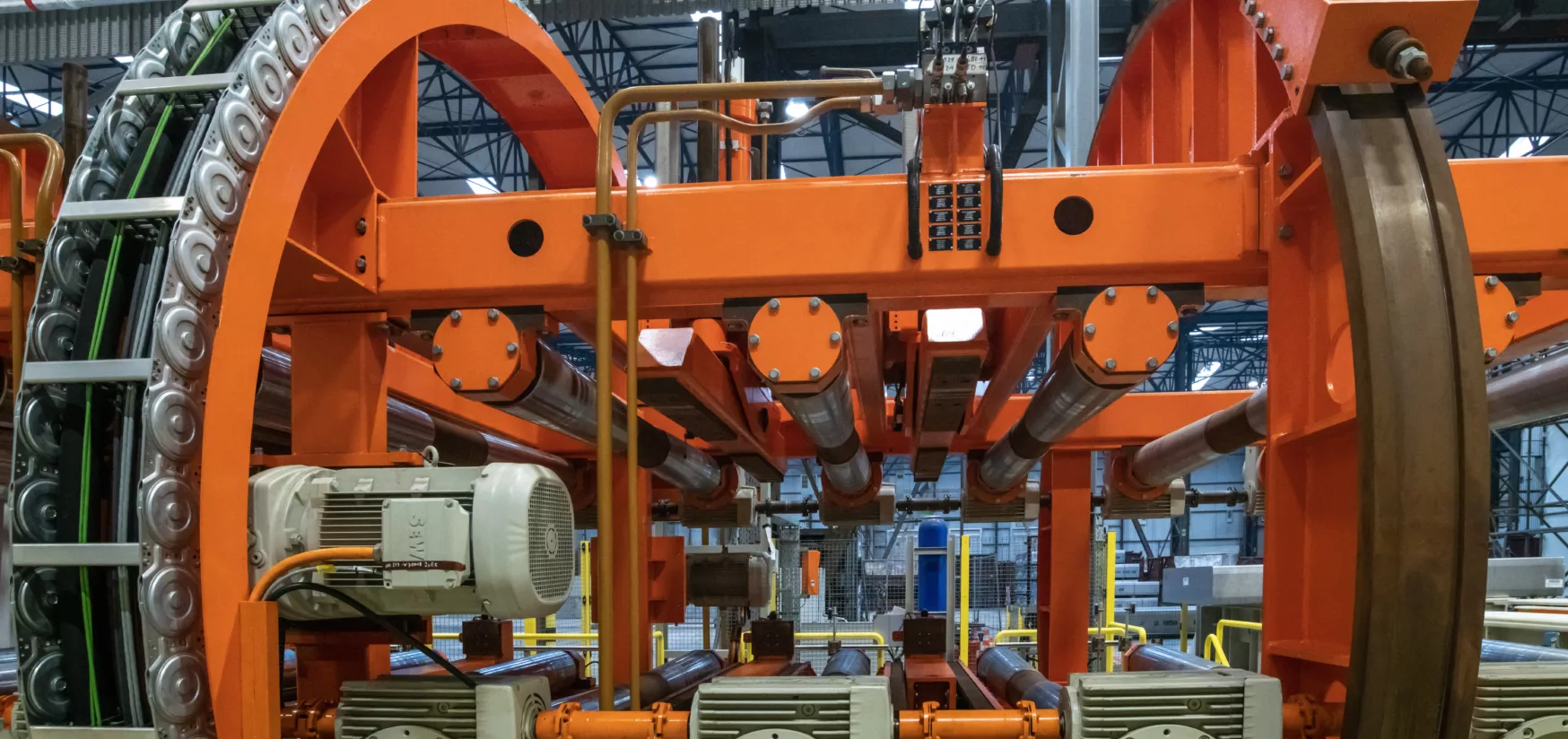

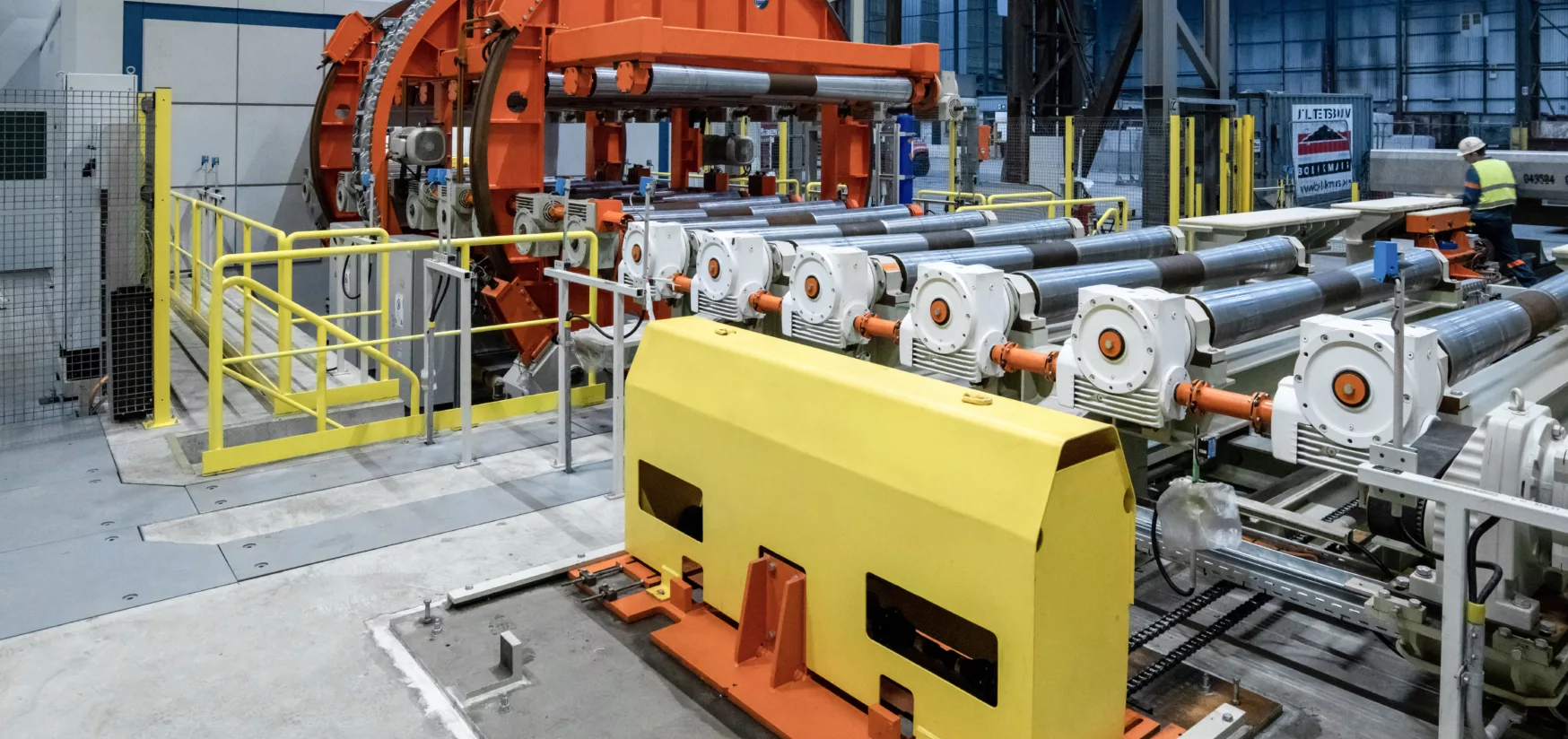

More good news from Aluminium Duffel. Today marks the start-up of our new high-tech milling installation, a major investment worth €26 million. The investment will further strengthen Aluminium Duffel's position as one of the leading aluminium rolling mills in Europe and will enable the company to grow further. The milling installation has a capacity of no less than 400,000 tonnes of aluminium per year.

A milling installation provides the top and bottom of an aluminium rolling block with a cleaner surface by removing or milling a layer. This is necessary to continue the rolling process. Until now, an amount of the slabs were milled in the former sister company in Koblenz. "Our widest slabs, which are essential for our customers in the automotive sector, are now milled in-house, which gives us more independence. Thanks to the high-tech properties of the installation, we can make the milling process more sustainable, an important step towards our environmental goals. In short, in this way we continue to invest in a sustainable future for our company, for our people and for our environment," says Koen Libbrecht, General Manager at Aluminium Duffel. The most recent acquisition of a cut-to-length line with enhanced width capabilities, in addition to the milling installation, underscores Aluminium Duffel’s ambition to become the state of the art provider of flat-rolled aluminium products.

Aluminium Duffel started the construction of a new 2500m² production hall in December 2022. Subsequently, the construction of the milling installation was started, which took about a year.

On the 25th of September at 9.15 am the first slab was milled on the milling installation in the presence of Duffel’s mayor Sofie Joosen, Bart Steukers (CEO Agoria), Paul Voss (European Aluminium Association), and the entire management team, project staff and press representatives.

Do you have any questions about the new logo or the new milling installation? Contact Alex Scholten, Marketing Director via alex.scholten@aluminiumduffel.com or tel +49 170 346 7376.